Load Capacity Test of a Sandwich Skateboard

Task:

The load capacity of a sandwich-structured skateboard deck is to be tested. For this purpose, the rear axle is fixed, while the front axle can move freely in the Y direction. A displacement of the axles in the X direction is not possible

Project Goal:

The objective of this experiment was to determine the load capacity of a sandwich-structured skateboard deck using finite element analysis conducted on ABAQUS CAE software. The test will involve fixing the rear axle in place, while allowing the front axle to move freely in the Y direction. Displacement of the axles in the X direction will not be possible. A surface load q will be applied to the two surfaces A1 and A2 on the top of the deck.

Solution:

In this engineering project, a simple shell model was developed and defined as a shell composite. The composite layup was specified with 7 layers, as explained previously, and the stress and deformation in the y-direction were calculated. Two different skin materials were used in separate cases while all other conditions were kept constant. To calculate the results, a pressure of 0.181 MPa was applied to two specified areas of the shell model. Two boundary conditions were used in the analysis. The first boundary condition, referred to as "fix," restrained rotational and displacement degrees of freedom in all three directions. The second boundary condition, referred to as "axel," allowed for a single degree of freedom in the y-direction. The analysis was carried out using a linear perturbation step. Overall, this analysis was performed to evaluate the effect of skin material on the stress and deformation of a composite shell model under a specified pressure load. The results will be useful in determining the most suitable skin material for the given loading conditions.

Results

Stress and deformation plots are calculated for both kind of composite materials and the results are explained below:

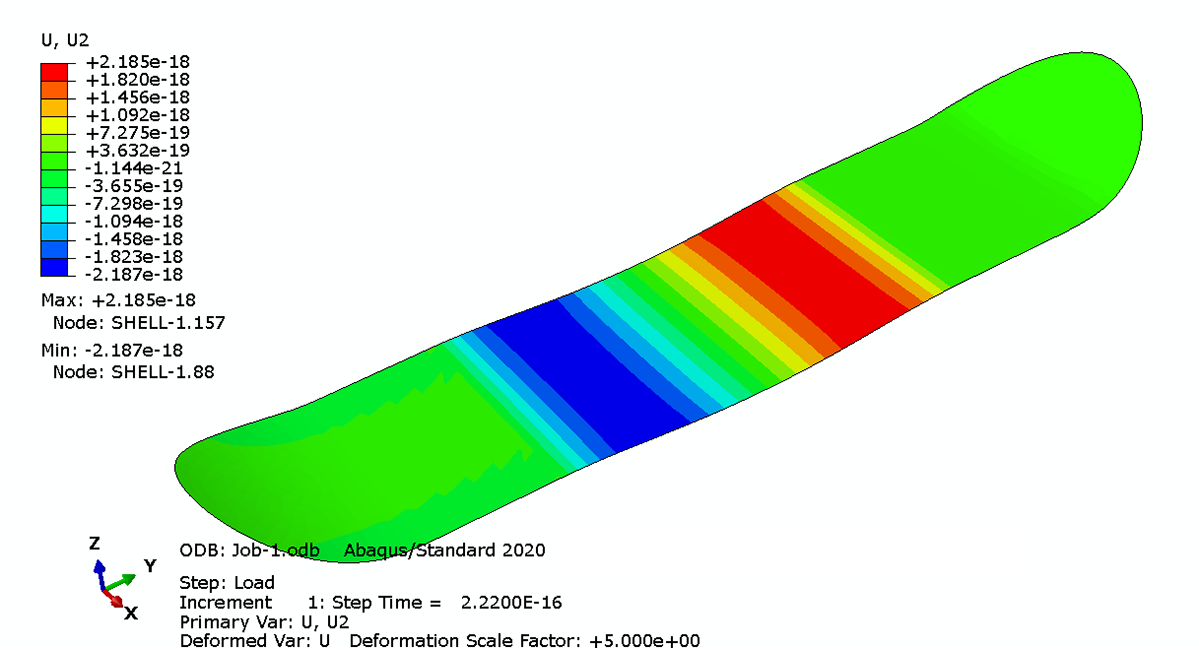

For HexPly 8552 UD IM10:

The material being analyzed exhibits maximum stress at the boundary where the specified conditions are applied. This figure has been scaled up by a factor of 4 to provide greater clarity with respect to the effects of the vertical loads. The upper side of the material is fixed, while the lower side is allowed to move in the y-direction. The maximum Mises stress value is determined to be 9.7 MPa, and the minimum stress value is 0 MPa at the non-loaded areas, which are identified in the figure with blue shading.

On the other hand, the minimum displacement in the structure is +2.185 x 10-18 mm, which suggests that the structure is experiencing some compression or inward movement in certain areas. The positive and negative signs in the plot only indicate the direction of displacement, which is taken as positive along the y-axis and negative in the opposite direction.

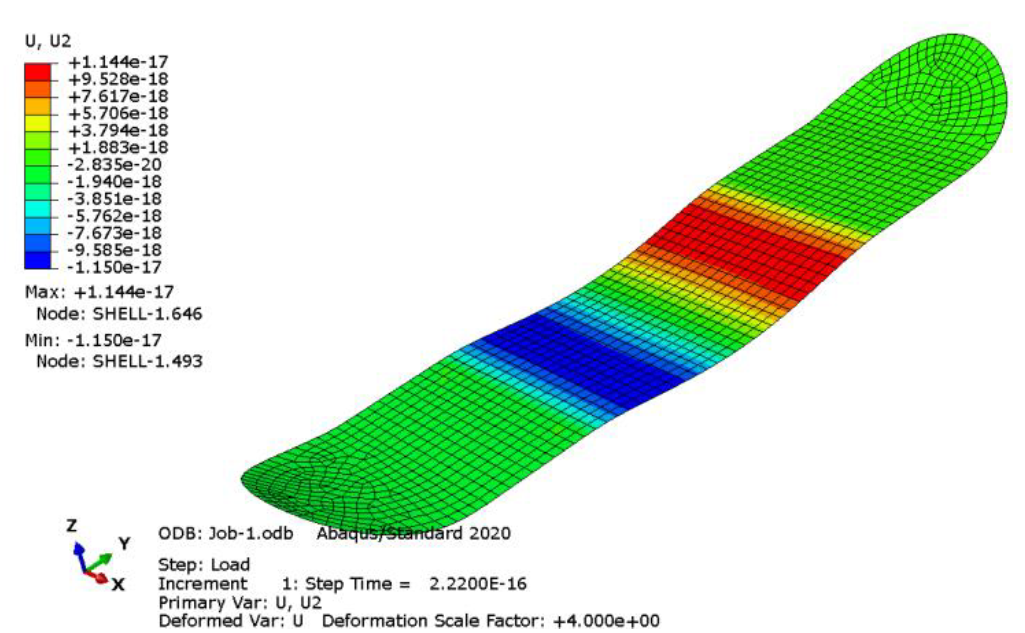

For S2-Glass-Epoxy:

The maximum stress occurs at the edge of the structure where the boundary conditions are applied. The vertical loads are illustrated to better understand their impact on the structure. The upper side of the structure is fixed, while the lower side is free to move in the y direction. The Mises stress at the maximum point is 31.93 MPa, while the non-loaded areas are indicated by the blue shading and have a minimum stress of 0 MPa.

The plot reveals slight deformation in the structure. The maximum deflection in the y-direction (U2) is -1.144 x 10-17 mm, which is considerably less than the required value of 15 mm stated in the problem statement. The minimum displacement is +1.144 x 10-17 mm, and the positive and negative signs only indicate the direction of displacement, which is considered positive along the y-axis and vice versa

Thank you for watching!

If you are in need of some kind of assistance in projects related to ABAQUS CAE, ANSYS, SOLIDWORKS or MATLAB. Feel free to contact me, I will be more than happy to help!

____________________________________

____________________________________

You can e-mail me at:

muhammad.nasir.q.100@gmail.com or muhammad.nasir.q.156@gmail.com

_______________________________

_______________________________

WhatsApp me at:

+92 3116072883